Vertical LAr Storage Tank – VT(Q) | High-Quality LAr Containers for ultimate cryogenic storage

Product Function

Certainly! The following are key highlights of the Perlite or Composite Super Insulation™ system and double jacket construction used in Deep South tanks:

Perlite or Composite Super Insulation™ System:

● Excellent thermal performance: Shennan storage tank has a thermal insulation system, which can ensure excellent thermal insulation performance, effectively reduce heat transfer and maintain the required temperature in the tank.

● Extended storage time: The insulation system employed in these tanks helps to extend the storage time of the material by reducing heat loss and heat gain.

● Reduced Life Cycle Costs: By minimizing energy consumption and maintaining temperature stability, insulation systems help reduce operating costs throughout the life of the tank.

● Lightweight Design: Utilizing lightweight perlite or Composite Super Insulation™ systems reduces load requirements during transportation and installation, making them more convenient and efficient.

Double sheath structure:

● Sturdy stainless steel liner: Shennan storage tanks are equipped with a strong stainless steel liner, which has excellent corrosion resistance and durability, ensuring the integrity of the storage tank and extending its service life.

● Reliable Carbon Steel Shell: The shell of the storage tank is made of carbon steel, known for its strength and widely used in industrial applications. It provides strong structural support and protection.

● Integrated Support and Lifting System: The carbon steel shell is cleverly designed with an integrated support and lifting system, simplifying transportation and installation procedures.

● Durable Corrosion Resistant Coating: The tank body has a durable coating with high corrosion resistance. This protective coating ensures tank reliability and longevity even when operating in harsh environments.

● Environmental protection: Shennan storage tank adopts durable coating and meets strict environmental protection standards to ensure environmental protection and safety during use.

By integrating these features, Shennan storage tanks have enhanced thermal performance, durability, ease of installation and corrosion resistance, ultimately improving overall efficiency and extending their service life.

Product size

We offer a comprehensive selection of tank sizes ranging from 1500* to 264,000 US gallons (6,000 to 1,000,000 liters). Our tanks are designed to withstand a maximum allowable working pressure of 175 to 500 psig (12 to 37 barg). Whatever your storage requirements, we have a tank size to fit your needs.

Product Features

Shennan storage tanks adopt a standardized design for cost-effective production and fast delivery.

● These tanks range in size from 1500 to 264,000 US gallons (6,000 to 1,000,000 liters) and have maximum working pressures ranging from 175 to 500 psig (12 to 37 barg).

● Available in horizontal and vertical options to meet different space and installation requirements.

● Our tanks are equipped with superior insulation systems such as perlite or Composite Super Insulation™, which provide excellent thermal performance, extended retention time and reduced operating and installation costs.

● The tank body adopts double-layer sheath structure, stainless steel liner, carbon steel shell, durable, easy to transport and install, and strong corrosion resistance.

● We pride ourselves on excellence in design and engineering, with a focus on low maintenance and user friendly features. Our storage tanks are equipped with easy-to-operate control valves and gauges, as well as comprehensive safety features to protect operators and equipment.

● All of our tanks comply with international standards, including major design codes and regional requirements, and are designed to meet seismic requirements for enhanced stability.

● In addition, we offer a product range dedicated to carbon dioxide (CO₂) storage, offering tailor-made solutions to meet specific needs. Shennan also provides customization services, allowing us to meet unique customer needs.

● We are capable of manufacturing small capacity tanks of 900 US gallons (3,400 liters) and tanks of 792 US gallons (3,000 liters) are manufactured in India to European factory standards.

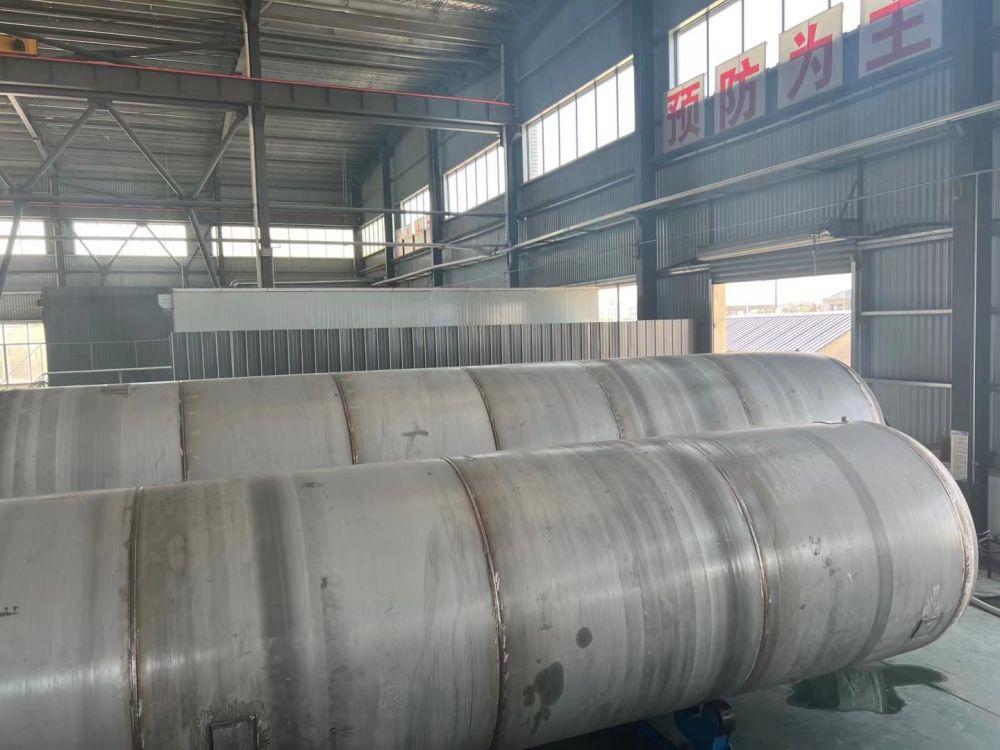

Factory

Departure Site

Production site

| Specification | Effective volume | Design pressure | Working pressure | Maximum allowable working pressure | Minimum design metal temperature | Vessel type | Vessel size | Vessel weight | Thermal insulation type | Static evaporation rate | Sealing vacuum | Design service life | Paint brand |

| m³ | MPa | Mpa | MPa | ℃ | / | mm | Kg | / | %/d(O₂) | Pa | Y | / | |

| VT(Q)10/10 | 10.0 | 1.600 | <1.00 | 1.726 | -196 | Ⅱ | φ2166*6050 | (4650) | Multi-layer winding | 0.220 | 0.02 | 30 | Jotun |

| VT(Q)10/16 | 10.0 | 2.350 | <2.35 | 2.500 | -196 | Ⅱ | φ2166*6050 | (4900) | Multi-layer winding | 0.220 | 0.02 | 30 | Jotun |

| VTC10/23.5 | 10.0 | 3.500 | <3.50 | 3.656 | -40 | Ⅱ | φ2116*6350 | 6655 | Multi-layer winding | / | 0.02 | 30 | Jotun |

| VT(Q)15/10 | 15.0 | 2.350 | <2.35 | 2.398 | -196 | Ⅱ | φ2166*8300 | (6200) | Multi-layer winding | 0.175 | 0.02 | 30 | Jotun |

| VT(Q)15/16 | 15.0 | 1.600 | <1.00 | 1.695 | -196 | Ⅱ | φ2166*8300 | (6555) | Multi-layer winding | 0.153 | 0.02 | 30 | Jotun |

| VTC15/23.5 | 15.0 | 2.350 | <2.35 | 2.412 | -40 | Ⅱ | φ2116*8750 | 9150 | Multi-layer winding | / | 0.02 | 30 | Jotun |

| VT(Q)20/10 | 20.0 | 2.350 | <2.35 | 2.361 | -196 | Ⅱ | φ2616*7650 | (7235) | Multi-layer winding | 0.153 | 0.02 | 30 | Jotun |

| VT(Q)20/16 | 20.0 | 3.500 | <3.50 | 3.612 | -196 | Ⅱ | φ2616*7650 | (7930) | Multi-layer winding | 0.133 | 0.02 | 30 | Jotun |

| VTC20/23.5 | 20.0 | 2.350 | <2.35 | 2.402 | -40 | Ⅱ | φ2516*7650 | 10700 | Multi-layer winding | / | 0.02 | 30 | Jotun |

| VT(Q)30/10 | 30.0 | 2.350 | <2.35 | 2.445 | -196 | Ⅱ | φ2616*10500 | (9965) | Multi-layer winding | 0.133 | 0.02 | 30 | Jotun |

| VT(Q)30/16 | 30.0 | 1.600 | <1.00 | 1.655 | -196 | Ⅲ | φ2616*10500 | (11445) | Multi-layer winding | 0.115 | 0.02 | 30 | Jotun |

| VTC30/23.5 | 30.0 | 2.350 | <2.35 | 2.382 | -196 | Ⅲ | φ2516*10800 | 15500 | Multi-layer winding | / | 0.02 | 30 | Jotun |

| VT(Q)50/10 | 7.5 | 3.500 | <3.50 | 3.604 | -196 | Ⅱ | φ3020*11725 | (15730) | Multi-layer winding | 0.100 | 0.03 | 30 | Jotun |

| VT(Q)50/16 | 7.5 | 2.350 | <2.35 | 2.375 | -196 | Ⅲ | φ3020*11725 | (17750) | Multi-layer winding | 0.100 | 0.03 | 30 | Jotun |

| VTC50/23.5 | 50.0 | 2.350 | <2.35 | 2.382 | -196 | Ⅲ | φ3020*11725 | 23250 | Multi-layer winding | / | 0.02 | 30 | Jotun |

| VT(Q)100/10 | 10.0 | 1.600 | <1.00 | 1.688 | -196 | Ⅲ | φ3320*19500 | (32500) | Multi-layer winding | 0.095 | 0.05 | 30 | Jotun |

| VT(Q)100/16 | 10.0 | 2.350 | <2.35 | 2.442 | -196 | Ⅲ | φ3320*19500 | (36500) | Multi-layer winding | 0.095 | 0.05 | 30 | Jotun |

| VTC100/23.5 | 100.0 | 2.350 | <2.35 | 2.362 | -40 | Ⅲ | φ3320*19500 | 48000 | Multi-layer winding | / | 0.05 | 30 | Jotun |

| VT(Q)150/10 | 10.0 | 3.500 | <3.50 | 3.612 | -196 | Ⅲ | φ3820*22000 | 42500 | Multi-layer winding | 0.070 | 0.05 | 30 | Jotun |

| VT(Q)150/16 | 10.0 | 2.350 | <2.35 | 2.371 | -196 | Ⅲ | φ3820*22000 | 49500 | Multi-layer winding | 0.070 | 0.05 | 30 | Jotun |

| VTC150/23.5 | 10.0 | 2.350 | <2.35 | 2.371 | -40 | Ⅲ | φ3820*22000 | 558000 | Multi-layer winding | / | 0.05 | 30 | Jotun |

Note:

1. The above parameters are designed to meet the parameters of oxygen, nitrogen and argon at the same time;

2. The medium can be any liquefied gas, and the parameters may be inconsistent with the table values;

3. The volume/dimensions can be any value and can be customized;

4. Q stands for strain strengthening, C refers to liquid carbon dioxide storage tank;

5. The latest parameters can be obtained from our company due to product updates.